Our Solutions

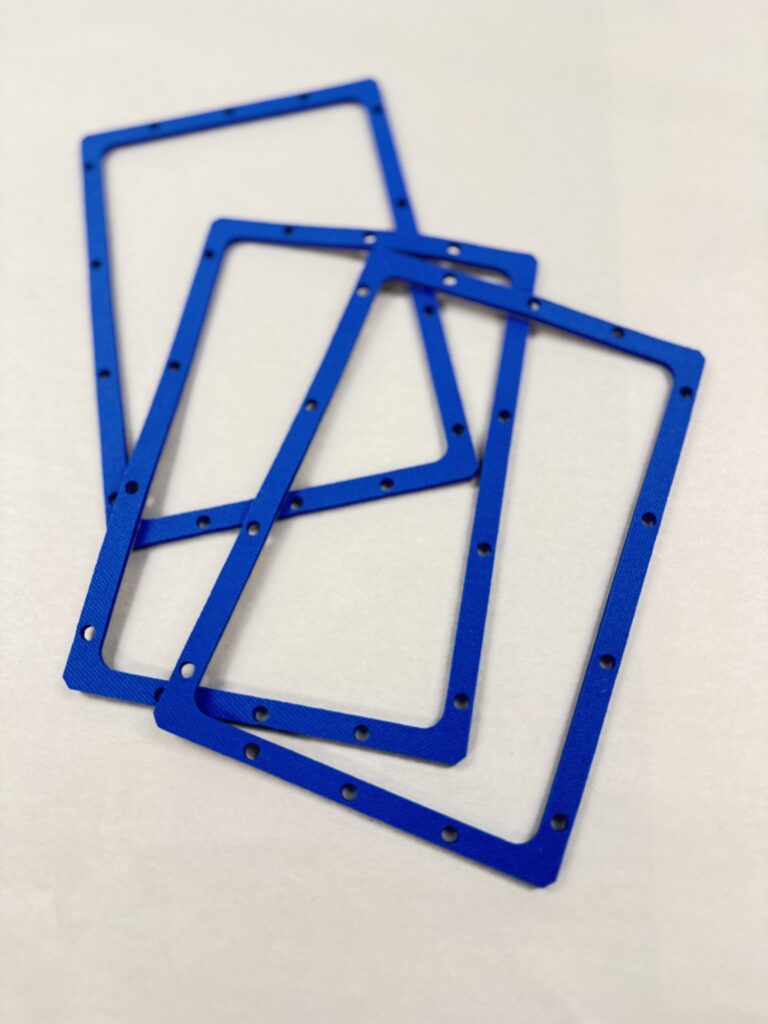

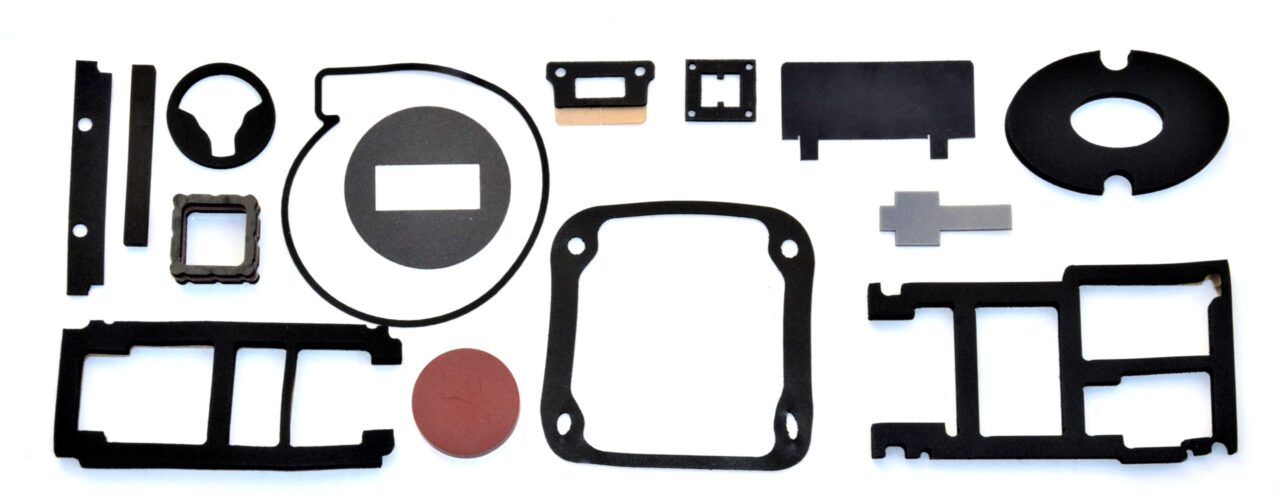

Gaskets & Seals

-

Properties and Benefits

-

Material Product Types

- Applications

Properties and Benefits

Available in a Wide Selection of Hardness

Low Compression Set

Wide Range of Operating Temperatures

Available in Thermally Conductive Silicone

Material / Product Types

Aerospace

Communications

Defense

Avionics

Automotive

Medical

Applications

- Low-modulus polymer material

- Innovative filler technology to achieve specific thermal and conformability characteristics

- Highly conformable to uneven and rough surfaces with very low-stress thermal gap pad compression

- Electrically isolating

- Variety of thickness and hardness

- Range of thermal conductivities

- Manufactured to customer size requirements

-

Proficiencies

- Performance

Proficiencies

Proven Knowledge

Deep engineering capabilities with expert knowledge of EMI RFI specifications

Field Proven

1,000’s of designs integrated into battle-harsh and commercially challenging environments

Proven Track Record

Orders delivered on time and to specification

Performance

From initial production design to full scale production

Continuous Improvement

Driven to maintain a zero-return rate

Collaborating

From project concept until completion

Our Solutions

Gaskets & Seals

Properties & Benefits

Available in a Wide Selection of Hardness

Low Compression Set

Wide Range of Operating Temperatures

Available in Thermally Conductive Silicone

Material/Product Types

Aerospace

Communications

Defense

Avionics

Automotive

Medical

Applications

- Low-modulus polymer material

- Innovative filler technology to achieve specific thermal and conformability characteristics

- Highly conformable to uneven and rough surfaces with very low-stress thermal gap pad compression

- Electrically isolating

- Variety of thickness and hardness

- Range of thermal conductivities

- Manufactured to customer size requirements

Proficiencies

Proven Knowledge

Deep engineering capabilities with expert knowledge of EMI RFI specifications

Field Proven

1,000’s of designs integrated into battle-harsh and commercially challenging environments

Proven Track Record

Orders delivered on time and to specification

Performance

From initial production design to full scale production

Continuous Improvement

Driven to maintain a zero-return rate

Collaborating

From project concept until completion

Offices

Sit diam eget tortor fringilla

Id pellentesque curabitur dui egestas id. Potenti rhoncus eget blandit sit. Suspendisse fames nam nibh imperdiet ipsum aliquet et dui enim. Vitae, neque, ullamcorper turpis vel euismod habitasse nisi.