Why EMI Gaskets

July 3, 2023

Autonomous military vehicles

December 20, 2023Articles

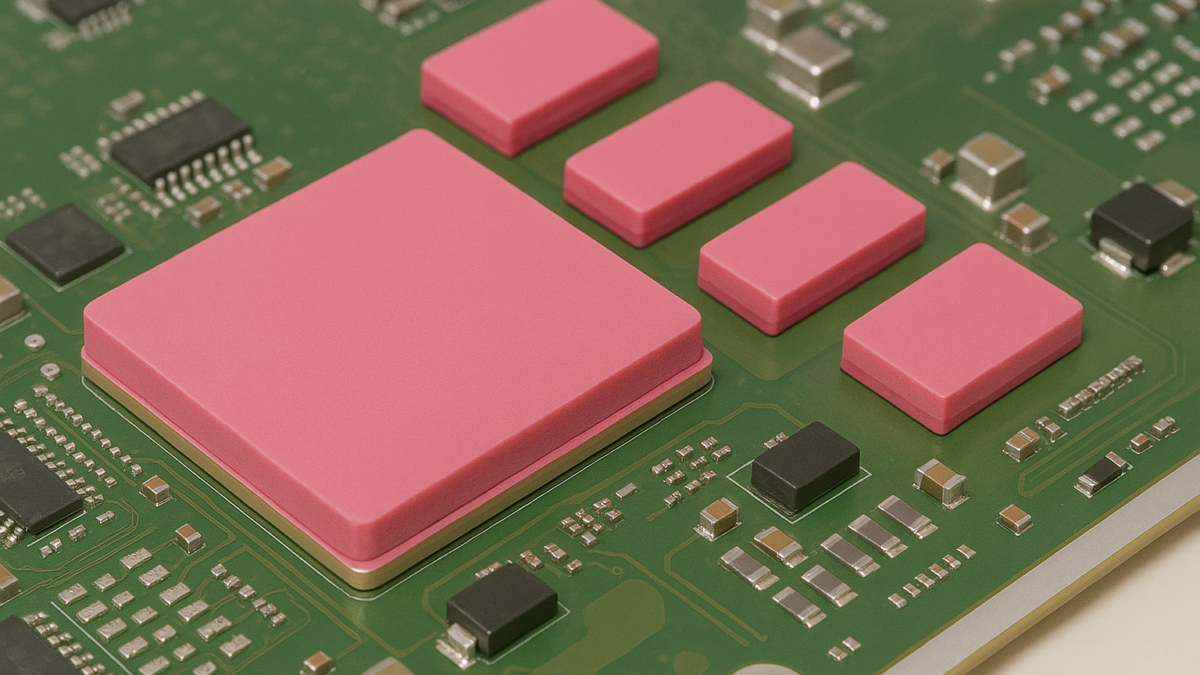

Thermal Gap Pads

PNA Technologies is a custom ‘Build to Print” Manufacturer of Thermal Gap Pads. Our process has used Bergquist, Fuji Poly, Boyd, T-Global and materials as defined by the customer.

Thermal Gap Pads

Thermal gap pads, also known as thermal gap fillers or thermal gap interface materials, are specialized materials used in electronics and thermal management applications. These pads are designed to fill the gaps between two surfaces, such as a heat-generating component (like a CPU or power amplifier) and a heat sink or heat spreader, to improve the thermal conductivity and heat dissipation between them. They are commonly used in electronic devices to prevent overheating and ensure optimal performance and reliability.

Key characteristics and uses of thermal gap pads include:

- Thermal Conductivity: Thermal gap pads are made from materials with high thermal conductivity, such as silicone or thermally conductive compounds. This allows them to efficiently transfer heat from the heat source (e.g., a microchip) to the heat sink.

- Conformability: These pads are designed to conform to irregular surfaces, filling any gaps or voids between the components. This ensures good thermal contact and minimizes air gaps, which are poor conductors of heat.

- Insulation: While thermal gap pads enhance thermal conductivity, they are typically electrically insulating. This is crucial in electronics applications to prevent electrical short circuits while improving thermal performance.

- Heat Dissipation: By improving thermal conductivity, these pads help dissipate heat from hot components, preventing them from overheating and potentially damaging themselves or nearby components.

- Vibration Damping: Some thermal gap pads also offer vibration damping properties, reducing the risk of mechanical damage or microcracks in electronic components due to vibrations.

- Ease of Installation: Thermal gap pads are relatively easy to install compared to other thermal management solutions like thermal paste. They come in various shapes and sizes and can be cut to fit specific applications.

- Non-Curing: Unlike thermal paste, which can harden over time, thermal gap pads are typically non-curing. This means they do not change their physical properties or require reapplication over time.

- Wide Temperature Range: These pads can operate effectively in a wide temperature range, making them suitable for both low and high-temperature environments.

- Variability: There are different types of thermal gap pads available, with varying thermal conductivities, thicknesses, and materials to meet specific thermal management requirements.

Thermal gap pads are commonly used in laptops, desktop computers, LED lighting systems, automotive electronics, and other applications where efficient heat dissipation is crucial for the proper functioning and longevity of electronic components. They provide a reliable and easy-to-use solution for managing heat in these devices.